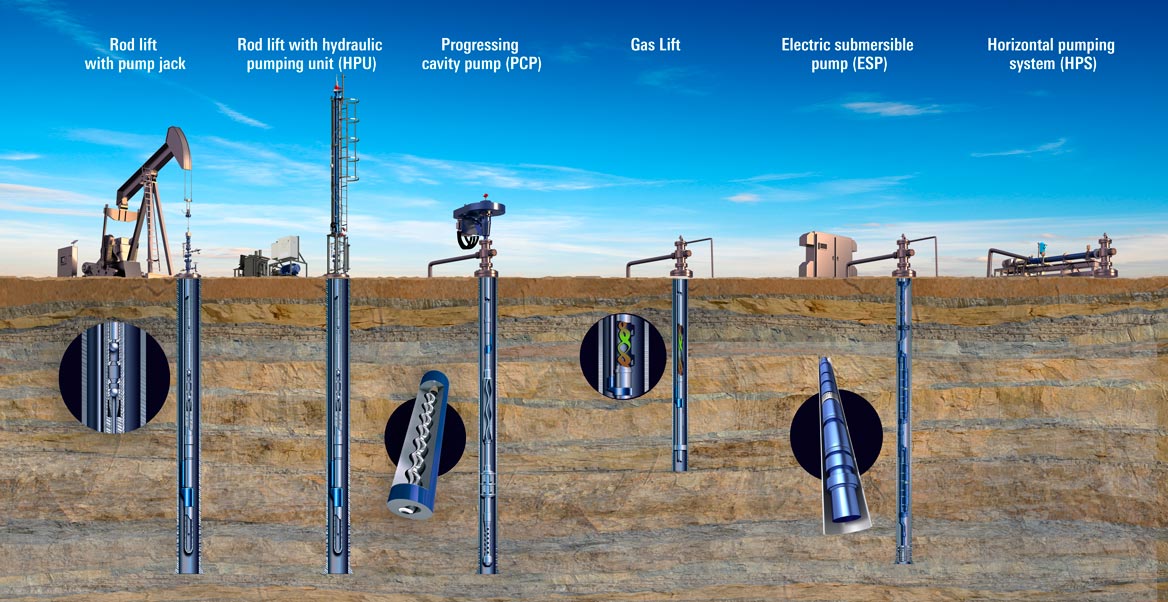

Oil and gas production is a complex process that requires a wide range of equipment and expertise. One of the most critical components of this process is the artificial lift system, which helps to increase the flow of oil and gas from the wellbore to the surface. There are several types of artificial lift systems available in the market, each with its own advantages and disadvantages. From the classic rod pumps to the modern gas lifts, understanding the different types of artificial lift systems can help oil and gas producers choose the best option for their operations. In this article, we will provide an overview of the most common types of artificial lift systems, their features, and applications, enabling you to make informed decisions about which system is right for your needs. So, whether you’re a seasoned oil and gas professional or just starting out, join us as we explore the fascinating world of artificial lift systems.

The Need for Artificial Lift Systems in Oil and Gas

Production

In many oil and gas wells, natural pressure from the reservoir is sufficient to bring the oil or gas to the surface. However, over time, this natural pressure will decrease, resulting in reduced production rates. To overcome this problem, artificial lift systems are used to increase the flow rate of fluids from the wellbore to the surface. These systems work by lowering a pump into the wellbore to lift the fluids to the surface. There are several factors that can cause a decrease in natural pressure, including the depth of the well, the viscosity of the fluids, and the permeability of the reservoir. As a result, the use of artificial lift systems is common in many oil and gas fields around the world. By using these systems, operators can maintain or increase production rates, and optimize the recovery of oil and gas reserves.

Types of Artificial Lift Systems

There are several types of artificial lift systems available in the market, each with its own unique features and applications. In this section, we will provide an overview of the most common types of artificial lift systems used in the oil and gas industry.

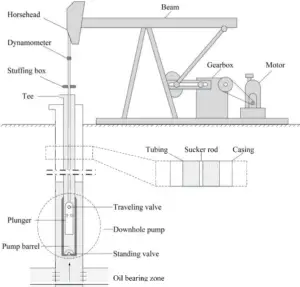

Rod Pump Systems

Rod pump systems, also known as beam pump systems, are the most commonly used artificial lift systems in the industry. These systems work by using a surface-mounted motor to drive a rod string that is connected to a downhole pump. The pump is lowered into the wellbore and is used to lift the fluids to the surface. One of the main advantages of rod pump systems is their simplicity and reliability. These systems can operate at high temperatures and pressures, and can handle a wide range of fluid viscosities. Additionally, rod pump systems are relatively inexpensive and require little maintenance.

One of the main advantages of rod pump systems is their simplicity and reliability. These systems can operate at high temperatures and pressures, and can handle a wide range of fluid viscosities. Additionally, rod pump systems are relatively inexpensive and require little maintenance.

However, rod pump systems are not without their drawbacks. These systems can be inefficient and can cause excessive wear and tear on the equipment due to the reciprocating motion of the pump. Additionally, rod pump systems are not suitable for deep wells or wells with high gas-to-liquid ratios.

Gas Lift Systems

Gas lift systems are another common type of artificial lift system used in the oil and gas industry. These systems work by injecting gas into the wellbore to reduce the hydrostatic pressure of the fluids and increase their flow rate to the surface. There are two types of gas lift systems: continuous and intermittent. Continuous gas lift systems use a constant flow of gas to lift the fluids, while intermittent gas lift systems use periodic injections of gas.

One of the main advantages of gas lift systems is their ability to handle high gas-to-liquid ratios and deep wells. Additionally, gas lift systems can be used to optimize production rates and reduce the risk of equipment failure. However, gas lift systems are not without their drawbacks. These systems can be complex and require specialized equipment and expertise to operate. Additionally, gas lift systems can be affected by changes in the gas composition, temperature, and pressure.

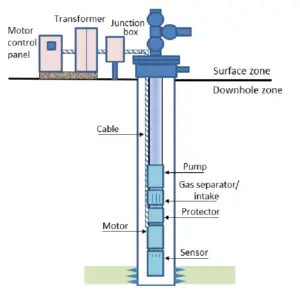

Electric Submersible Pump (ESP) Systems

Electric submersible pump systems, or ESP systems, are another type of artificial lift system commonly used in the oil and gas industry. These systems work by using a downhole electric motor to drive a centrifugal pump.

The pump lifts the fluids to the surface through a production tubing string. One of the main advantages of ESP systems is their ability to handle high volumes of fluids at high pressures. Additionally, ESP systems can be used in a wide range of well conditions, including high temperatures and corrosive environments.

However, ESP systems are not without their drawbacks. These systems can be expensive and require specialized equipment and expertise to operate. Additionally, ESP systems can be affected by changes in the fluid composition and can be prone to equipment failure.

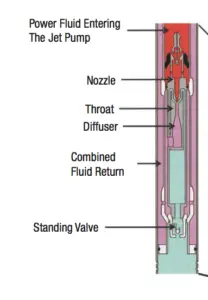

Hydraulic Jet Pump Systems

Hydraulic jet pump systems are another type of artificial lift system used in the oil and gas industry. These systems work by using a high-pressure fluid to create a low-pressure area that lifts the fluids to the surface. One of the main advantages of hydraulic jet pump systems is their ability to handle high volumes of fluids with high gas-to-liquid ratios. Additionally, hydraulic jet pump systems can be used in a wide range of well conditions, including high temperatures and corrosive environments.

However, hydraulic jet pump systems are not without their drawbacks. These systems can be complex and require specialized equipment and expertise to operate. Additionally, hydraulic jet pump systems can be affected by changes in the fluid composition and can be prone to equipment failure.

Progressive Cavity Pump (PCP) Systems

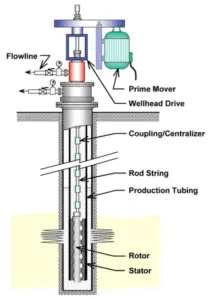

Progressive cavity pump systems, or PCP systems, are another type of artificial lift system commonly used in the oil and gas industry. These systems work by using a helical rotor and stator to create a positive displacement that lifts the fluids to the surface.

One of the main advantages of PCP systems is their ability to handle high volumes of fluids with high gas-to-liquid ratios. Additionally, PCP systems can be used in a wide range of well conditions, including high temperatures and corrosive environments.

However, PCP systems are not without their drawbacks. These systems can be expensive and require specialized equipment and expertise to operate. Additionally, PCP systems can be affected by changes in the fluid composition and can be prone to equipment failure.

How to Choose the Right Artificial Lift System for Your Well

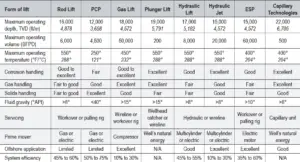

Choosing the right artificial lift system for your well depends on a variety of factors, including the well conditions, production goals, and economic considerations. In general, the best artificial lift system for your well will be the one that can optimize production rates while minimizing costs and downtime.

To select the right artificial lift system, it is essential to work with experienced oil and gas professionals who can provide expert advice and guidance. These professionals can help you evaluate the different systems available, analyze the well conditions, and determine the best option for your needs.

Conclusion – The Importance of Selecting the Right

Artificial Lift System for Optimal Production Artificial lift systems are a critical component of oil and gas production. By selecting the right system for your well, you can optimize production rates, reduce costs, and maximize the recovery of oil and gas reserves. Whether you choose a classic rod pump system or a modern gas lift system, understanding the different types of artificial lift systems and their applications can help you make informed decisions about which system is right for your needs. So, work with experienced professionals, evaluate your options, and choose the best artificial lift system for your well